About us

VERBRUGGE offers you its “Factory of the Future”

to celebrate its 80th birthday

Protection against wear and corrosion of mechanical parts.

After 80 years in its historical premises in Lille-South, Verbrugge moved into its new Templemars plant in August 2021!

Still dedicated to the wear and corrosion protection of mechanical parts, it has an ultra-modern line which is twice as big, with double the capacity, and twice the responsiveness!

Fully automated, it will adapt to every need: more nickel varieties, more treatments, more finishes on more metals, …

The environment is at the heart of the factory design to minimise its impact.

Water is especially looked after: it is permanently treated and recycled without any discharges to the drains.

The latest installed technologies also allow us to consume fewer resources, particularly electricity.

Just after it opened, our factory and processes were ISO 9001 (re)certified.

+ 80 years of excellence and still going strong !

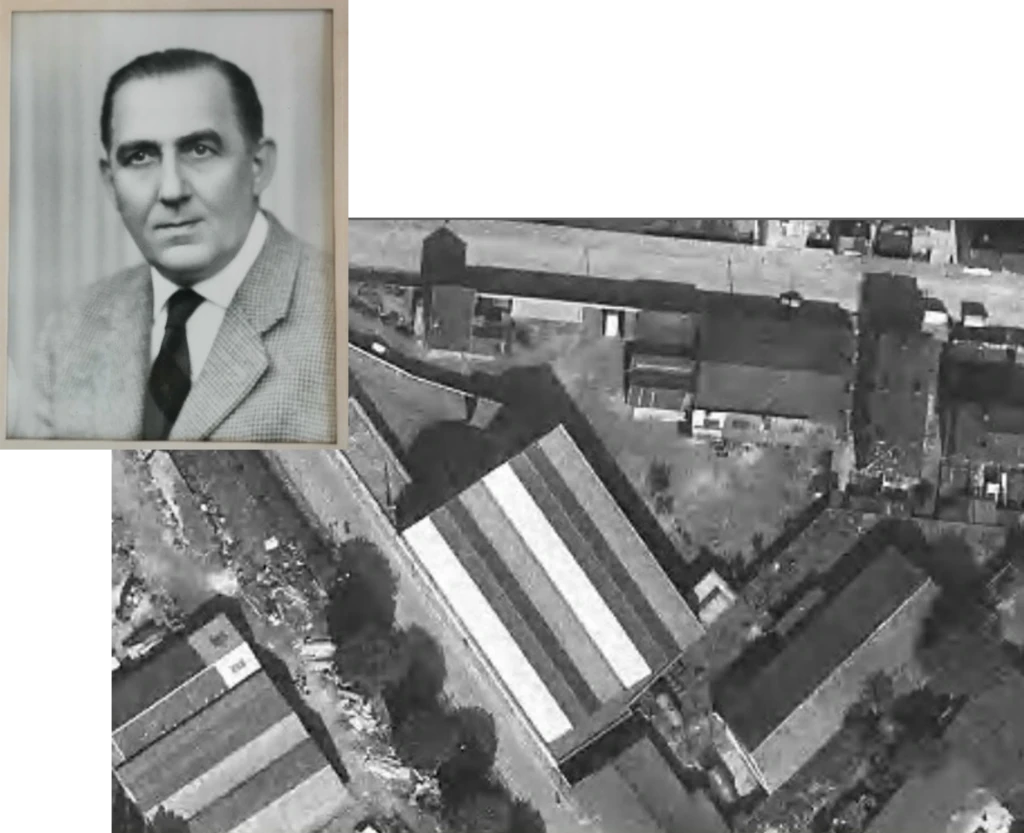

Since its creation in 1941 by Gaston Verbrugge, our company has charted an exceptional course that has continued to flourish over time. The journey began with the installation of one of the first hard chrome-plating tanks in France, laying the foundations for our expertise. Barely a decade later, in 1951, we extended our reach throughout the region, with a team of 8 employees already dedicated to regional industry.

In 1963, Jacques Verbrugge took over the leadership of the company, injecting a new dynamic that propelled us towards new horizons. Under his leadership, we gradually diversified our skills, expanding our capacity to accommodate parts of up to 6 metres in length. It was also at that time that our ‘grinding’ department was created, to meet the ever-changing demands of the French industrial markets. The company employed 19 people at the time.

1991 saw the arrival of the third generation: Jean-François and Jean-Louis Verbrugge. Thanks to their youth, our new leaders made their mark by rapidly introducing partial automation of our hard chromium plating processes. That change was a major turning point in our story, gradually moving the company on from “craft” to “industry”.

The pivotal year of 2001 marked a memorable new page in our adventure: the arrival of the “ELECTROLESS NICKEL PLATING” department. A ‘revolution’ – as this new coating was at the time – spread throughout the company, shaking up established norms and injecting new energy into our team. It was not just the introduction of a new surface technology, but the catalyst for a complete transformation of the company.

Our electroless nickel plating line was also revolutionary: from 2001 it was fully automatic and pioneering, as it was already controlled by Artificial intelligence.

In the years that followed, the company grew its knowledge and experience in this new electroless nickel plating market. The succession of trials, failures and successes gradually forged our reputation as a solid specialist in the trade. Our team was also growing, with many talented people joining our technical, production, quality and chemical departments.

In 2006, our company received its first quality label in the form of ISO certification. Then came IATF (automotive) certification. It was also during at that time that our quality laboratory was set up, with sophisticated equipment to guarantee our customers, now European and no longer just French, the level of quality demanded by those markets.

Those years were the springboard that propelled our company to becoming one of the European leaders in the profession.

In 2018, with a staff of 35, the idea of ‘expanding the walls’ was already growing. Our site in Lille was becoming cramped as demand continued to grow.

The “Nickel-Chrome 3 Mille” project took shape.

It peaked in 2021 with our move to the new Templemars site.

It was the symbol of our 80 years of growth, doubling our production capacity and opening up new horizons for the creation of new products thanks to our new state-of-the-art multi-treatment line.

We are now at the cusp of an exciting new era, in which our strengthened resources will allow us to take our place in the new global markets linked to the energy transition we are living through in the 21st century.

Not satisfied with this new factory, our investments are ongoing, …

In line with our taste for innovation and performance, we recently installed two ‘cobots’ – robotic arms that assist humans – to handle medium loads (up to 100kg) safely and efficiently.

Moreover, our investment in a 6th heat treatment furnace and an additional robot are boosting our responsiveness in delivering tailored treatments.

Finally, a composite nickel (with particle inclusions) deposition unit is currently under development. In the short term, it will make it possible for us to offer our customers extremely high-performance tip coatings.